Degreening

Introduction

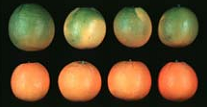

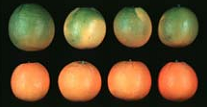

Degreening also is called gassing, sweating or curing. Its purpose is to improve external skin color and export market acceptance. Improve external skin color and export market acceptance.

Timing of De-greening

Ethylene treatment should be given immediately after harvest.

Ethylene De-greening Methods

* Gas Treatment * Liquid Treatment

Gas Treatment

The general procedure for de-greening citrus with ethylene gas involves exposing green-skinned fruit held at a high temperature and relative humidity to low concentrations of ethylene for several days. The source of ethylene can be a high-pressure gas cylinder or an ethylene generator.

The ethylene gas treatment procedure for effective de-greening should adhere to the following protocol:

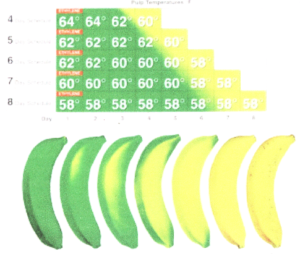

Temperature: 28-29°C (82-85°F) for humid production areas

20-25°C (68-78°F) for arid production areas

Relative Humidity: 90-96%

Ethylene Concentration: 3-5 ppm

Duration: ≤ 2 days

Grapefruit: 48 hours

Oranges: 24-36 hours

Tangerines: 6-12 hours

The source of ethylene can be a high-pressure gas cylinder or an ethylene generator.

High Pressure Cylinders

The flow of ethylene from the high pressure cylinder into the de-greening rooms is finely controlled by a two-stage regulator, needle valves and flowmeters.

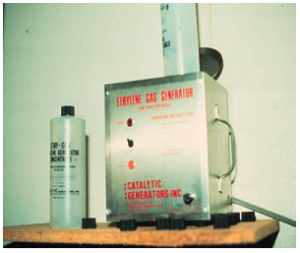

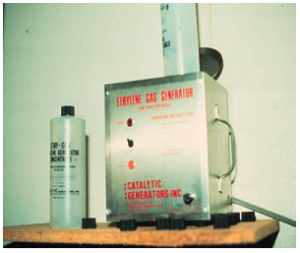

Ethylene Generator

A commercially available electric ethylene generator is available for de-greening citrus.

It converts ethanol, in the presence of heat and a catalyst, to ethylene. The generator is located inside the de-greening room.

Liquid Treatment (Ethephon)

The general procedure for de-greening citrus with liquid ethylene (ethephon) involves dipping green-skinned fruit in a tank of water at ambient temperature to low concentrations of ethylene for several minutes or less.

The liquid ethylene treatment procedure for effective de-greening should adhere to the following protocol:

Water Temperature: ambient (22-29°C) (72-85°F)

Water Sanitation: potable, 150 ppm hypochlorous acid, pH 6.5, fungicide

benomyl (500 ppm) or thiabendazole (1000 ppm)

Ethephon Concentration: 500 ppm

Duration: 1-3 minutes

The source of ethylene is the chemical [(2chloroethyl) phosphonic acid], which is a liquid ethylene-releasing compound with the chemical name of ethephon.

Important notes:

*The water should be sanitized with 150 ppm hypochlorous acid (2.4 pints of household bleach in 100 gallons of water) and maintained at a pH of 6.5.

*The sanitizing strength of the wash water should be frequently tested with the appropriate meters and/or test strips, and adjusted when necessary.

* A fungicide is usually incorporated in the water (500 ppm benomyl or 1000ppm thiabendazole).

Degreening Chamber considerations:

| CO2 level |

< 1% |

| Air circulation(velocity) |

1 room volume/min |

| Ventilation |

1-2 air changes/hr |

*Air circulation within the degreening room should produce about one change per minute. * Outside air ventilation should be adequate to maintain carbon dioxide level below one percent.

* Adequate insulation of the walls and ceiling of the de-greening chamber/room is necessary to avoid over-heating.

*The room should be designed so the internal air movement is horizontal.

* The treatment chamber should be well insulated in order to maintain the desired ethylene concentration.

Important degreening notes:

* Fruit do not have to be dry before treatment. However, grapefruit will not de-green well if the peel is moist.

* Recommended degreening conditions :

| Temperature |

82o to 85o F |

| Relative humidity |

92 to 95% |

| Ethylene |

1 to 5 ppm |

* Warmer or cooler temperatures slow de-greening.

* A high RH is necessary during de-greening to maintain peel freshness and prevent dessication.

*Higher ethylene concentrations do not speed up the rate of degreening, but increase postharvest decay.

Notes on Ethylene Usage:

Climacteric:-

Apple, apricot, avocado, banana, feijoa, mango, papaya, passion fruit, peach, pear, plum, tomato and watermelon.

Nonclimacteric :-

Blueberry, cherry, cucumber, fig, grape, grapefruit, lemon, melon, olive, orange, pineapple, strawberry and tamarillo.

- Ethylene is known to affect the following plant processes.

- Stimulates the release of dormancy.

- Stimulates shoot and root growth and differentiation (triple response)

- May have a role in adventitious root formation.

- Stimulates leaf and fruit abscission.

- Stimulates Bromiliad flower induction.

- Induction of femaleness in dioecious flowers.

- Stimulates flower opening.

- Stimulates flower and leaf senescence.

- Stimulates fruit ripening.

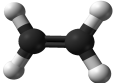

Ethylene is a small unsaturated hydrocarbon consisting of two carbon atoms joined by double bond with the formula C2H4 . It is found naturally as a gaseous component in petroleum deposits, and the ability of ethylene to polymerize has been utilized by petrochemical industry to produce the now –ubiquitous plastics.

Ethylene is a small unsaturated hydrocarbon consisting of two carbon atoms joined by double bond with the formula C2H4 . It is found naturally as a gaseous component in petroleum deposits, and the ability of ethylene to polymerize has been utilized by petrochemical industry to produce the now –ubiquitous plastics.